Φ26×12 マックス. 孔 CNC 角金属 孔マークとシーリングライン 3 CNC軸

適用される産業:

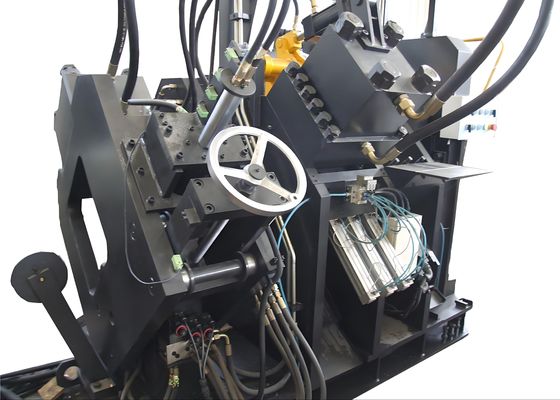

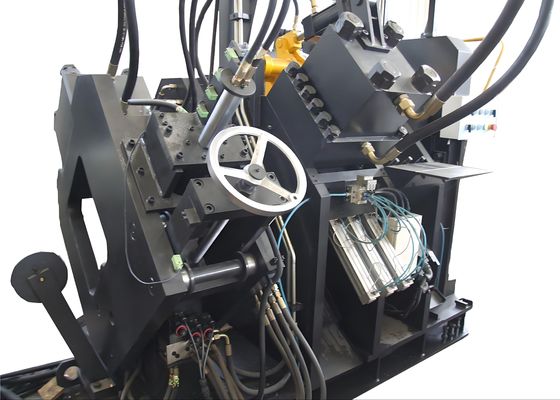

この機械は,角鋼のパンシング,マーク,シート作業を行うために開発された特殊な装置です.角鉄塔産業の基本的な加工要件に対応するために特に調整されています塔の製造に不可欠な角鋼部品の精密かつ効率的な処理を保証します.

仕様:

| 機能 |

パンシング,マーク,切断 |

| 角の大きさ (mm) |

40×40×3 140×140×12 |

| 最大空白の長さ (m) |

12 |

| 完成品の最大長 (m) |

10 |

| マックス パンシング (直径 х厚さ) (mm) |

Φ26×12 ((材料:Q345 510N/mm2) |

| 側ごとにパンチ |

2 |

| 打撃力 (kN) |

630 |

| 標識力 (kN) |

630 |

|

切断力 (kN)

|

1800 |

| 標識文字のグループ |

4 |

| グループごとに文字数 |

12 |

| 文字の寸法 (mm) |

14×10×19 |

| 切断モード |

片刃切断 |

| CNC軸 |

3 |

| 角の加熱速度 (m/min) |

80 |

| 液体システムの冷却方法 |

水冷却 |

| 処理精度 |

GB2694 に準拠する |

| プログラム機能 |

キーボードとUSBインターフェイスによる入力 |

| 尺寸 (mm) |

28000×6500×2200 |

製品組成:

この装置は主に横軸輸送機,回転式積載システム,フードイン輸送機,CNCフードインキャリ,パンシングモジュール,マークモジュール,切断モジュール,荷下ろしコンベヤーと水力コンベヤー電気・気力システムなど

製品の特徴:

1作業部品の高効率と一貫した精度を提供します. すべてのキー水力,気力,電気部品は輸入品です.

2各側には3つのセットのパンチとマールが装備されており,異なる直径の3種類のパンチを収容できます.PLCによって制御されます.3つのセットの模具は,パンシング基準マークを調整するために同期的に移動することができます.

3コンピュータは中国語/英語のインターフェースを備えており,ユーザーフレンドリーな操作を可能にし,ワークピースの図面表示をサポートします. プログラミングは簡素化されています.ローフティングソフトウェアによって生成されたプログラムデータを直接利用できますプログラムを編集する際には,ワークピースのサイズ,穴の直径,参照マーク,ワークピースの量のみ入力する必要があります.

4. CNC フィードキャリーは,フォトエレクトリックエンコーダーでフィードバック情報を提供するサーボモーターで駆動されます. 高い位置付け精度を保証するために,閉ループ制御が採用されています.

5標識,パンシング,シーリングプロセスは完全に自動化されています.すべての完成したアングル鋼部品は,気圧転覆装置によって卸荷され,労働の強度を削減できます.

6制御システムは,ホストコンピュータ,CNCシステム,サーボモーター,PLC,および外部検出センサーから構成されています.処理操作は,単に作業部品の寸法入力によって開始されます.さらに,プログラムは,作業部件番号に応じて保存,選択,表示,送信することができます.

7. マークユニットは,優れた硬さを保証する閉ざされたフレーム構造を採用しています.マークユニットに4つの文字ボックスが固定されており,プログラム制御で選択できます.標識基準マークは任意に設定できます.孔,マーク,シーリング用のシリンダーは,より大きな仕様があり,NCキャリは,アップグレードされ,より堅牢なモデルであり,クランプは,構造的な強度が向上しています.

角鉄塔産業における共通仕様と加工シナリオをカバーするこれらのサンプルにより,ユーザーは,機器の加工品質,精度,工芸品設備の性能と,特定の生産要求との相容性を評価するための具体的な基準として機能します.

In the construction of ultra-high voltage (UHV) transmission lines—where towers are required to withstand extreme meteorological conditions and heavy loads—this equipment plays a crucial role in processing the angle steel components that form the main framework of the towers塔体,交差腕,その他の主要な構造部品に使用されるアングル鋼の掘削とスタンプ操作を熟練して実行します.塔の全体的な安定性を確保するために正確な寸法と堅牢な接続を確保する.

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!