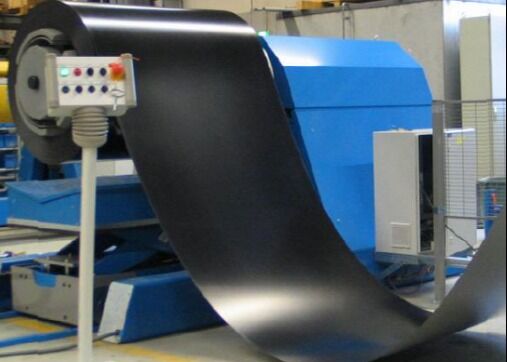

7000kg シングル・スチール・コイル・ウェイト 自動ケーブル・トレイ・デコイラー ポンシング・コールド・ブーイング 生産ライン

製品紹介:

自動ケーブルトレイデコイル,パンチングと冷たい曲がり生産ラインは,マルチプロセスのオリジナルの単一のシート,不間断の生産,セットの解巻,平衡,パンチング,形成を達成することができます一つの連続生産で刈り取り生産ラインは,高生産速度,オンラインパンシングと連続型造形生産,操作が簡単で労働力が少ない.

製品構成:

| 原材料 |

Q235 冷たい物で巻いたシート |

| 適した鋼コイル外径 |

フ1200mm |

| 適した鋼コイル内径 |

フ508mm |

| 原材料の幅 |

<1050mm |

| 原材料の厚さ |

1~3mm |

| シングルスチールコイル重量 |

≤7000kg |

| ケーブルトレイのサイズ |

幅100~500;高さ50~200 |

| 実効的な作業速度 |

3~10m/min |

生産プロセス:

デコイルリベラー材料ループ サーボフィッダー 多ステーションパンチャー (切断) - メインロール前者 ファイナルプロファイル出力

主要な構成要素

電源送電プラットフォーム 1セット

適用: 打孔シートを形作機に輸送する

構造: 主にフレーム,パワー装置,コンベアベルト,幅調整装置,ガイド装置などで構成される,ガイド装置付きのベルトコンベアーを採用します. 給餌速度は無限調整可能です.鋳造機の速度に一致する.

| 最大給餌速度 |

15m/min |

| 最大許容される給餌幅 |

≤1050mm |

| モーターパワー |

7.5kw |

| 餌の長さ |

16000mm |

カンチレバー調節型形作機 -1セット

適用: ロールを曲げる過程で,必要な完成したプレート形を最終的な必要な横断形にロールするために使用されます.

構造: 形状装置は,電動,減速器,螺旋斜面ギアによって駆動される,コンチレバー形状機械モードを採用します.

床幅と腰の高さの違いのある製品を製造する際には,タッチ画面でパラメータを設定するだけで便利で速く信頼できます.

形状ロールはプロのソフトウェアで設計されています.素材は高品質の模具鋼 Cr12 ででき,冷却後の硬度は HRC58 ~ 62 (アメリカの材料 D2/D3 に相当します).ローラー表面は,完成後に磨きローラーは高精度で長寿です

主な成形部品には2つの成形マシンが含まれます.成形マシンのベースには移動装置が装備されており,それは事前に設定されたガイドレールで長さに沿って移動することができます.2台とC型パルリンの製造のための1台,

パラメーター: 形状のパス: 10+12パス

| 形作りの機械の軸径 |

φ100mm (最終設計による) |

| 総電源 |

約30KW (最終設計による) |

| 自動車ブランド |

シメンス・バダー |

| 最大線形速度 |

5~15m/min |

1組の電源のない支架 (合計長さ12m)

ストックが動かない状態で,合計で2つのセクションがあり,各セクションの長さは6メートルです.素材ストックは取り外す構造です.輸送や様々な場所での使用に便利です.

液圧システム 1セット

適用: 解巻とパンチングの電源サポートを提供する.

構造: ポンプと蓄積器の組み合わせ構造が採用され,パンシングとシーリングは速く,生産ラインの速度が向上します.空気冷却冷却器は,高負荷と高温下で仕事と生産の要件を満たすために熱を散布するために使用されます液圧システムは高速パンシング,ロール形成,冷たい曲線生産ラインの切削に適した高速液圧システムです.主な水力部品は,北京 Huade 製品を採用.

主な部品は:油ポンプ,モーター,液圧バルブ,電磁弁,フィルター,液圧油タンクなどです.

電動制御ユニット-1セット

部品の仕様パラメータ,数量およびシステムパラメータは,タッチスクリーンを通して設定できます.操作指示の複数のセットを同時に保存することができます生産ラインの異常の場合,アラーム機能があります. 制御システムを通して生産ライン全体の動作を監視できます..停電または異常停止後,処理は,以前に設定された作業パラメータに従って継続できます.

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!